Barrel Ten Quarter Circle

Barrel Ten Quarter Circle is state of the art ISO 9001:2015 and CCOF certified facility where vintage dated, cork/screw-cap finished varietal wines are bottled. Although Barrel Ten Quarter Circle operates independently, it belongs to the umbrella of Bronco Wine Company, a company that has been a pioneer and leader in the wine industry since its founding in 1973.

Barrel Ten opened for business in the year 2000, bottling on a 5-day/24-hour capacity basis. By the year 2005, the facility increased its capacity for manufacturing from 1 to 3 bottling lines. Such increase in bottling ability was in direct response to the growth and expansion of company and customer owned product bottling demands.

Over the years, even with the company’s increased demand for company and/or customer owned products, Barrel Ten has been able to maintain high production efficiencies. Nationally distributed company owned brands such as Charles Shaw and Trader Joes, Crane Lake, Stone Cellars, and Coastal Vines are among many of the brands bottled on site.

As a large manufacturer of finished wine goods in the Napa Valley, Barrel Ten has increased their recycling efforts in all possible areas; this is done with the goal of reducing the impact on the environment from waste generated via the manufacturing process. The company has made large efforts to refine the recycling program in place in order to include all conceivable materials into the recycling stream.

Barrel Ten utilizes the principle of “Reduce, Reuse, and Recycle” as a standard for the program to be successful. Following this principle, Barrel Ten earned TRUE Zero Waste Gold certification in 2016.

As a subsequent benefit to the recycling efforts made by the company, Barrel Ten Quarter Circle has significantly decreased the landfill tonnage by more than 70% since 2010, when the company put an additional emphasis on the recycling program. In recent years, Barrel Ten has been able to maintain a more stable landfill tonnage compared to the beginning of their recycling traceability.

All efforts to increase the recycling efforts and diminish the annual landfill tonnage have allowed to company to maintain a landfill diversion greater than 90% since their 2016 certification.

Some of the most critical items attributed to the success of Barrel Ten in Zero Waste recycling include:

- Selecting the correct partners in the recycling industry that can handle the volumes generated from our operations.

- Consistently exploring ways to recycle and/or reuse non-common items.

- Examples include: Utilizing plastic pallets (have a longer life than wood pallets), purchasing raw materials in bulk that allow for large reusable containers to be used instead of individual boxes (i.e. corks), and the constant returning and reusing of wooden pallets, frames and dunnage for glass items.

- Persistent exploring for new recycling/re-using avenues of non-common items (i.e. Label cores and webbing, different types of plastic films, etc.).

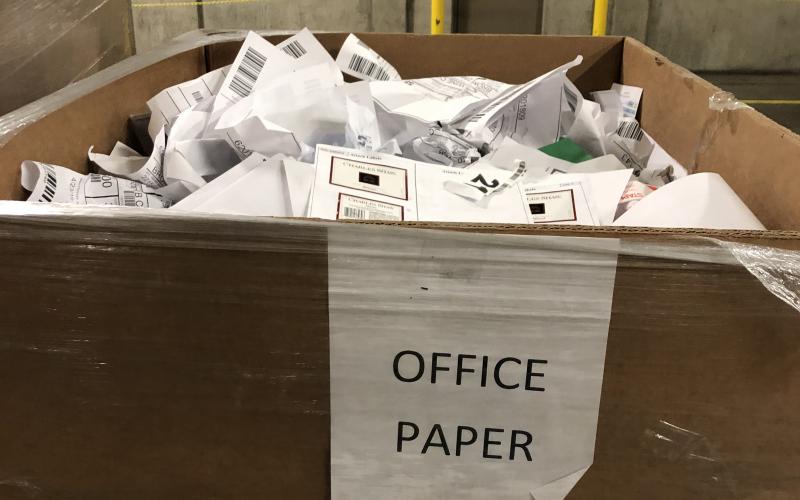

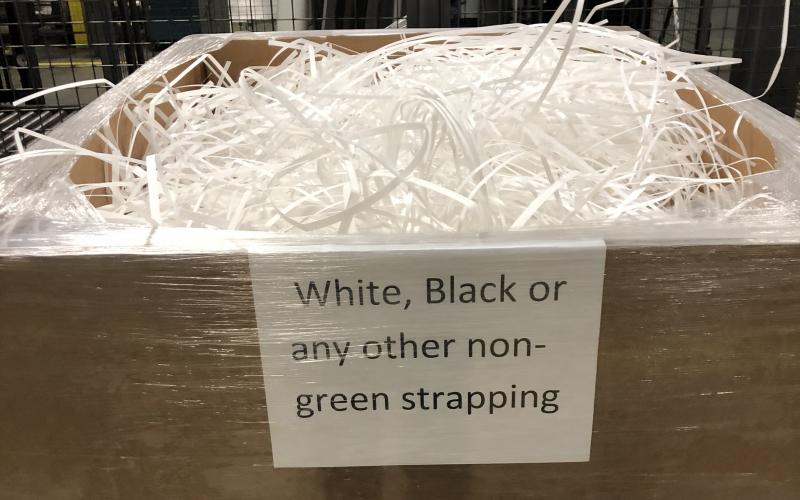

- Sorting of all recycling materials to the most basic level in order to maximize the recyclability and purchase value of the material.

-

- Examples include: Individual 30 yard containers for landfill and glass disposal; baling of sorted color and clear PET/LDPT Plastics and cardboard; shredding and separating multi-color plastic strapping; separating hard plastics, films, loose paper/cardboard, scrap metal; etc.

- Availability of recycling receptacles and containers throughout the facility, which in turn, encourage employees to recycle.

- Hazardous, E-waste, and Universal Waste are treated, separated, and disposed of according to Local, State, and Federal regulations via a third party recycler.

- Consistent monitoring, training, and participating of employees to maintain and elevate the recycling culture and efforts within the workforce.

- Consistent efforts from the company to raise the bar in recycling performance.

- Full support and commitment from ownership to pursue and (at the minimum) maintain the certification level.

- In the spirit of giving back to the community, a portion of Barrel Ten Quarter Circle’s yearly recycling revenue is used to purchase gifts for the United States Marine Corps “Toys for Tots” program.